新闻中心

NEWS CENTER

联系我们

CONTACTS US

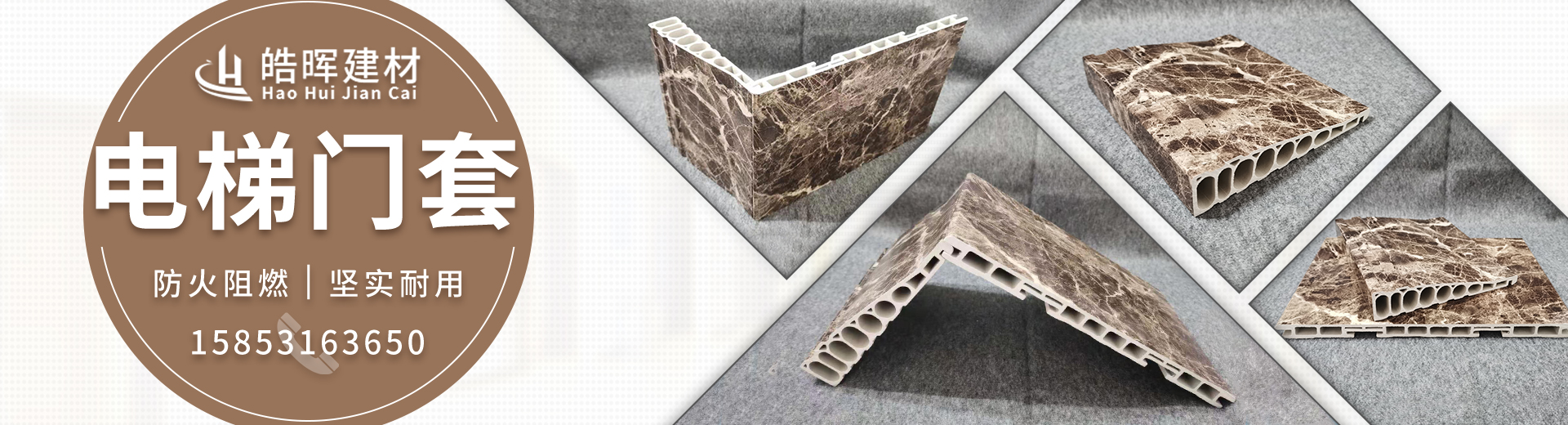

济南皓晖建材有限公司,总部位于中国泉城——山东济南,是一家专业生产销售石塑电梯门套,仿大理石电梯门套的专业厂家。皓晖建材在电梯门套生产行业很多年,凭着优质的产品质量和完善的售后服务,在全国各地都有我们的工程案例。

我们本着“以质量求生存 ,靠管理出效益,凭信誉赢口碑,以实干筑辉煌”的经营理念,公司将立足于当代建材现代化发展前沿,依靠科技、勇于探索,以优质产品优良服务、信誉与广大用户携手共创辉煌。

联系电话: 15853163650

工厂地址:山东济南章丘区(欢迎广大客户来厂勘察)

行业新闻

COMPANY NEWS

大理石平板平面度误差的检测方法

2016-05-20 17:19:56 文章来源:www.jnhaohui.com

大理石平板平面度的检测误差的方法有四种:三点法、对角线法、最小乘二法以及最小区域法这四种。

There are four ways to measure the flatness of the marble flat plate: three points method, diagonal method, least square method and the minimum zone method four.

三点法是用实际被测大理石平板表面上相距最远的三点所组成的平面作为评定基准面,用来平行这个基准面,并具有最小距离的两包含平面间的距离作为平面度误差值。

Three point method is with actual measured marble slab surface on the farthest away from the plane as the evaluation reference surface, used to parallel the datum and has a minimum distance of two contains inter plane distance as the flatness error value.

对角线检测法是以通过实际被大理石平板测表面上的一条对角线,用来平行另一条对角线所作的评定基准面,用来平行于这个基准面且具有最小距离的两包含平面间的距离作为平面度误差值。

Diagonal line detection method is through actual marble slab test on the surface of a diagonal line, used to parallel the other diagonal as the evaluation reference surface to parallel to the datum and has a minimum distance of two contains inter plane distance as the flatness error value.

最小乘二检测法是以实际被测大理石平板表面的最小二乘平面作为评定基准面,用来平行于最小二乘平面,并具有最小距离的两包含平面间的距离作为平面度误差值。最小乘二平面是使实际被测大理石平板表面上各点与该平面的距离的平方和为最小的平面。此方法计算较为复杂,一般需要计算机处理。

Minimum by second detection method is to actual measured marble plate surface of the least-squares plane as the evaluation reference surface for parallel to the plane of the least squares, and with the minimum distance of two contains inter plane distance as the flatness error value. The least square of the two plane is the sum of the square of the distance between the points on the surface of the marble slab and the plane of the plane. The calculation of this method is more complex, generally requires computer processing.

最小区域检测法是以包含实际被测表面的最小包含区域的宽度作为平面度误差值,是符合平面度误差定义的评定方法。

The minimum zone detection method is a method to evaluate the definition of flatness error, which is based on the minimum width of the region containing the actual measured surface as the flatness error.

上一篇:KTV设计内部三大细节处理

下一篇:建筑石材产品保养维护方式